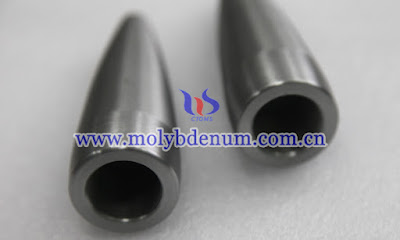

Molybdenum alloy piercing plug is produced by high-quality molybdenum powder mixing with titanium, zirconium and carbon powders, and processed by mixing, forming, sintering, and machining. The density of finished products is ≥9.4g/cm3.

As molybdenum metal has many characteristics, such as high temperature resistance, oxidation resistance, high hardness, it is usually used to be the raw material for piercing plug to be used for piercing seamless steel tubes, such as stainless steel, brazing steel, high temperature alloy steel, molybdenum and other special parts.

The plug is actually a vulnerable part in the steel industry. With the increasing scarcity of molybdenum resources and the continuous rise of molybdenum prices, improving its service life and the comprehensive yield in the production process are the main subject of researchers. Fortunately, after 40 years of development, China has made many revisions and optimizations in terms of raw material formula, production technology and cost control.

Initially, the plus is made of pure molybdenum powder, but its service life is short and people has to make further research. After adding some rare earth elements, the plug can obtain longer service life. The elements include Ti, Zr, C and so on.

The addition of titanium powder can activate the surface of the molybdenum particles during the sintering process, and can improve the alloying degree and uniformity of finished plug during the sintering process. The effect of adding zirconium powder is similar to that of titanium powder, and the activity strengthening effect of zirconium is greater than that of titanium.

The addition of carbon is very important. Most of carbon forms hydrocarbons with hydrogen in the hydride during the sintering process, and removes the hydrogen in the hydride to the limit, so as to achieve the effect of activation and combustion. Meanwhile, it can interact with titanium and zirconium at high temperatures. Forming two-phase refractory metal carbides TC and ZC can strengthen molybdenum.