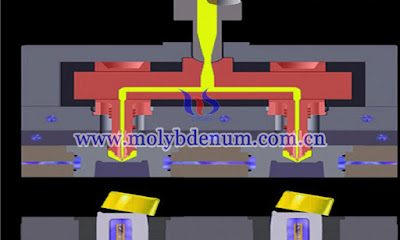

There are two kinds of steel pipes – stainless steel pipes and welded steel pipes, according to their production methods. Compared with welded steel pipes and other steels, stainless steel pipes are pierced with tools such as plugs and mandrels.

These piercing tools not only participate deformation, but also are the most important factors that determine whether the main processers of steel pipe production, such as piercing and pipe rolling can operate normally. As a matter of fact, the production process of seamless steel pipe also reflects the technical level of these tools. In other words, the research on internal deformation tools is an important subject of seamless steel pipe technology research.

Molybdenum alloy plugs are used to pierce seamless tubes of different materials, such as stainless steel, brazing steel, high-temperature alloy steel and other special parts. As they work in high temperature and harsh environments, the material of plug requires the characteristics of high temperature strength, high temperature oxidation resistance, long service life, corrosion resistance and not easy to stain glass.

Therefore, the material of the plug usually adopts molybdenum alloy with a composition of Ti, Zr, C and Mo. Molybdenum alloy plug is produced in a powder metallurgy process, has a higher recrystallisation temperature and higher strength compared to pure molybdenum, and is readily deformable even at room temperature. These effects are due to mixed crystal formation between Mo and Ti as well as the precipitation of ZrC as a dispersoid.

Actually, the materials to be used depends on what kinds of steel pipes to be pierced. Different materials of pipes have different characteristics and thus require plugs to meet different working conditions. As a professional manufacturer of molybdenum and tungsten, Chinatungsten Online can offer you various kinds of piercing plug. Certainly, customized designs are welcomed. Send us drawings and inform us its detailed application, we will offer you the best solution.