Pure molybdenum has very high melting point, which makes it useable in most high temperature applications. However, with the development of molybdenum alloy, titanium-zirconium-molybdenum (TZM) alloy has become a good all-round candidate no matter in vacuum furnace industry, medical diagnostic equipment industry or other industries.

Although TZM alloy products are expensive than pure molybdenum, in certain applications the additional cost is offset by its increased strength at elevated temperatures.

People add trace elements such as titanium and zirconium to molybdenum to remove the grain boundary embrittlement phase through solid solution strengthening of trace elements, and its reactant acts as a dispersed phase to strengthen the alloy to improve its performance.

The suggested applied temperature is between 700 and 1400 degrees Celsius. Like pure molybdenum, it starts to oxide at 400 degrees Celsius, and rapidly oxides at above 500 degrees Celsius. However, at operating temperatures exceeding the recrystallization temperature of pure molybdenum (900 to 1,100 degrees Celsius), TZM is much stronger. And in load-bearing applications exceeding 1300 degrees Celsius, TZM is twice as strong as pure molybdenum.

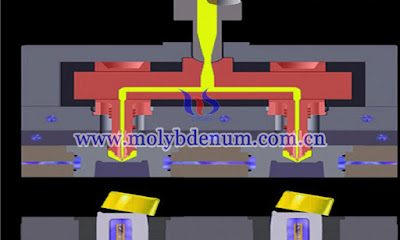

In the vacuum furnace industry, TZM is the material of choice for load-bearing hearths and horizontal posts; in the medical diagnostic equipment industry, it is used as the material of choice in rotating anodes in X-ray tubes; in hot runner system, it can be machined into nuzzle tips and keep plastic in melt status.

However, when applied in hot runner systems, TZM rods will be machined into nuzzle tips, and during this process, some problems may occur, such as split, cracking, unmachinable, tools easy to be damaged, or debris easy to stick on tools.

Reasons for these problems are complex, for example, when tools are easy to be damaged during processing, it probably shows signs that TZM rods has high hardness. However, it cannot be assured it is the problem of hardness, the selected tools may also cause this problem. If you require lower hardness, debris are easy to stick on the surface of tool. Therefore, there should be a comprehensive solution for these problems.

Chinatungsten is a professional manufacturer of molybdenum. Our knowledgeable and experienced refractory metal sales engineers are standing by to help you select the best metal for your application and solve whatever problems you meet.

If you have any inquiry of TZM rods, please feel free to contact us:Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595