Inventory shortage in mines stabilizes molybdenum concentrate price; prices and quantity of steel biddings show poor performance and thus ferro molybdenum price is under pressure and manufacturers have strong risk aversion. Due to few new increased orders and weakening support from costs, prices in molybdenum chemical and product market is in a downward trend.

Jiangsu Dragons bid out 150 tonnes of ferro molybdenum in July with price of RMB 105.500 per tonne, down RMB 3,000 per tonne from last month; HBIS Group tenders 60 tonnes of ferro molybdenum for June in RMB 106,500 per tonne, down RMB 1,500 per tonne from compared with last time.

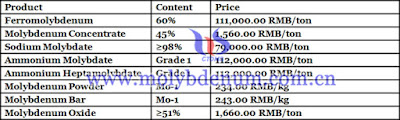

Prices of molybdenum products on Jun. 27, 2018

Picture of molybdenum oxide

If you have any inquiry of molybdenum products, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.