Carbon steel is widely used around the globe for the construction of bridges of sizes ranging from the very large to the very small, but now many bridges around the world are approaching the end of their useful life because carbon steel bridges do not have the corrosion resistance benefits offered by chromium, molybdenum and other alloying elements.

The forward-looking design of the Soderstrom Bridge with duplex stainless steel highlights the benefits of building bridges from structural stainless steel in coastal areas or where deicing salts are used. Molybdenum-containing stainless steels will play an ever-increasing role in much-needed infrastructure upgrades and new builds around the world for the benefit of the environment and the people who depend on them.

Duplex stainless steel bridge structures were praised for their attractive appearance when they were first introduced, with novel designs emerging such as Singapore's Double Helix Bridge and the world's longest mono-cable suspension bridge with a curved deck in Xiamen, China. Nowadays, designers are increasingly looking at the properties of the material beyond its aesthetics. In many applications, even in concealed applications, its strength and corrosion resistance are used to create structures that are lighter than carbon steel in the past. The materials used and less maintenance is required.

All duplex grades are at least twice as strong as 316 stainless steel and have good weldability for a wide range of applications. This material of bridge structures is gaining popularity around the world due to their longer service life and lower maintenance requirements.

While all steel is 100% recyclable, options with stainless steel have a lower environmental footprint. If the stainless steel is selected correctly, the bridge structure will not fail over time. Stainless steel can achieve a near-infinite life expectancy when properly maintained to specification requirements. It also does not require any environmentally harmful surface treatment to resist corrosion

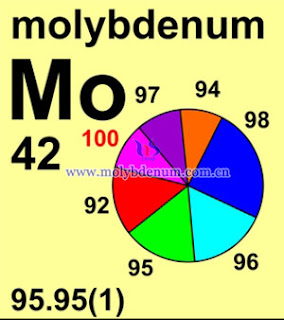

The Soderstrom Bridge was built with 2404 duplex stainless steel, the first bridge to be designed with this grade of stainless steel. This stainless steel contains 1.6% molybdenum, which contributes significantly to its crevice corrosion and pitting resistance. In fact, this type of stainless steel not only has twice the yield strength of 316 stainless steel, but also has improved atmospheric corrosion resistance.

Xiamen Mountains-to-Sea Trail (Health Footpaths) starts at Dongdu Cruise Plaza and ends at Guanyin Mountain Beach. It includes an 11km elevated trail and seven long-span node bridges, as well as newly remodeled green spaces along the walkways. The project also connects eight mountain ranges, namely Huwei Mountain, Xianyue Mountain, Yuanshan Mountain, Xueling Mountain, Hutou Mountain, Jinshan Mountain, Huzi Mountain and Guanyin Mountain, as well as 3 waters of Yundang Lake, Wuyuanwan and Hubin Reservoir. The idea of the walkway is to connect these oasis of harmony and tranquility with bridges, creating a continuous path independent of the busy life of the city below.

The construction time of Xiamen health footpaths was short, and the hills and forests in the environment were extremely challenging. Therefore, designers chose to use highly prefabricated components. Due to their low weight, these components could be transported to the site without heavy machinery, with minimal damage to vegetation.

Stainless steel containing molybdenum is used through the all footpath. For example, Hemei Bridge, one of seven footbridges that are part of the Xiamen Mountains to Sea Trail, a 23-kilometre large-scale network of footpaths, elevated walkways, and footbridges, the suspension system consists of a three-part main cable (fully locked steel cables) and 36 hanger cables (stainless steel spiral strands). The main cable joins the tips of the V-shaped mast and connects the mast to the abutments. The eccentrically arranged hanger cables connect the curved deck to the main cable. The V-shaped mast is situated along the central symmetry axis, stabilized by four guy cables.

If you have any inquiry of molybdenum products, please feel free to contact us:Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595