Glass is prized because of its clarity, beauty and numerous versatilities. The presence of molybdenum is helpful for its manufacturer and related products for daily use as the material has high strength at high temperature and also has corrosion resistance to molten glass.

There are records in history for the use of glass by humanity, which can be traced back to the era when primitive people used obsidian glass naturally formed by lava as a knife and cutting. In the development process from ancient history to modern times, glass has proved its practicality in countless applications and has become an indispensable part of daily life. Nowadays, molybdenum is also indispensable for glass manufacturing.

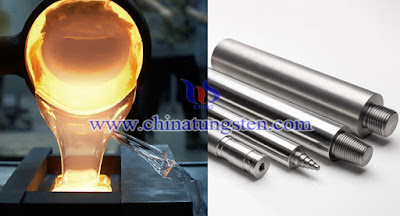

With the advent of electricity, engineers began to design electric furnaces to replace coal or gas fuel furnaces traditionally used to melt glass. Early designs tried to relied on electric arc and radiation to heat glass, but these techniques were not widely accepted. In the 1950s, researchers discovered that molten glass can conduct electricity, and the molybdenum metal electrode can directly heat the glass by passing an electric current through the molten glass.

After that, the use of molybdenum was increased. Molybdenum electrode can be side-entry or bottom-entry. There are also molybdenum stirrers to help to make the melt uniform. The molten glass can protect the molybdenum components from the rapid oxidation of air at high temperatures, so that they have a long and reliable service life. The designer uses inert cooling gas or water cooling to protect the electrode part outside the glass from being oxidized.

The molybdenum component can also protect the refractory materials of the furnace from wear and corrosion, as a refractory brick that covers vulnerable areas as ‘armor’. Even in the absence of molten glass protection, advanced coatings make these components resistant to oxidation during cold start.

If you have any inquiry of molybdenum electrode , please feel free to contact us:Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595