Molybdenum copper is alloy of molybdenum and copper. It is a great alternative to tungsten copper for weight sensitive applications, with many good properties.

1. High electrical and thermal conductivity. Molybdenum is a better element for electricity conductivity except for gold, silver and copper in the metals. Therefore, molybdenum copper alloy composed by molybdenum and copper have very high electrical and thermal conductivity.

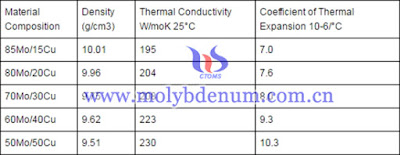

2. Adjustable low coefficient of thermal expansion. The coefficient of thermal expansion of copper is higher, but the coefficient of thermal expansion of molybdenum is very low. Therefore, the low coefficient of thermal expansion can be made by different proportion of the components according to the requirements, in order to make them appropriate and combine with other materials, avoid the damage of thermal stress caused by large differences in coefficient thermal expansions.

3. Special high temperature property. The melting point of molybdenum is 2 610, and the melting point of copper is only 1083, molybdenum-copper alloy have good strength property and definite plasticity in ordinary temperature. And if the temperature exceeds the melting point of copper, the copper will change to liquid and evaporate to absorb heat, to make cooling effect. This performance can be used as special-purpose high-temperature materials, such as the nozzle throat which can be resist combustion temperature of gunpowder, electrical contact which under high-temperature electric arc, and so on.

4. Molybdenum copper alloy is non-magnetic. Both molybdenum and copper are non-magnetic non-ferrous metals. Hence the composition of Mo-Cu alloy is an excellent non-magnetic material.

5. Molybdenum copper alloy has low gas content and a good vacuum performance. Either molybdenum or copper, its oxides easy to restore, their N, H, C and other impurities can easily be removed, thereby maintaining low outgassing and makes full use of performance of the vacuum.

6. Molybdenum copper alloy has good machinability. Because of high hardness and brittleness, it is difficult to machine the pure molybdenum. Mo-Cu alloy, because of copper's incorporation, the hardness reduced and plasticity increases, so it is beneficial to machining, and can be processed into complex shapes components.

If you have any inquires concerning molybdenum products, please don't hesitate to e-mail us by :

sales@chinatungsten.com or

info@chinatungsten.com