TZM (Titanium-Zirconium-Molybdenum) is an alloy made of Titanium (Ti), Zirconium (Zr), and Molybdenum (Mo). It is known for its high strength, high temperature resistance, low thermal expansion, and excellent creep resistance.

These properties make it a popular material for use in high temperature and high stress applications, such as furnace linings, aerospace components, and mechanical seals. The alloy is also known for its low density, good thermal conductivity, and high dimensional stability.

TZM alloy is used in various high temperature and high stress applications because of its unique properties. Some common uses of TZM alloy include:

Aerospace industry: TZM alloy is used in components for aerospace and aircraft due to its high strength, corrosion resistance, and ability to withstand high temperatures.

High-temperature furnace components: TZM alloy can withstand temperatures up to 1800°C, making it suitable for use in high-temperature furnace applications, such as heat exchangers and furnace linings.

Mechanical seals: TZM alloy is used as mechanical seals in pumps and compressors due to its low coefficient of friction, high wear resistance, and high strength.

Sealing applications: TZM alloy is used in sealing applications due to its good creep resistance, high dimensional stability, and resistance to high temperatures.

Medical devices: TZM alloy is used in medical devices and implants due to its biocompatibility and low density.

High-temperature fasteners: TZM alloy is used for high-temperature fasteners and bolts due to its high strength and heat resistance.

These are just a few examples of the many uses of TZM alloy. The specific application will depend on the desired properties and the operating conditions of the system.

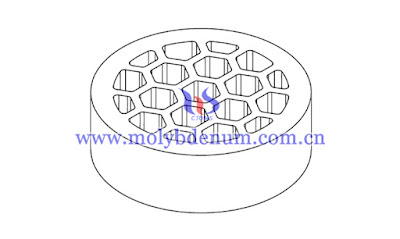

Rings in TZM material own the characteristics of the molybdenum alloy and thus can be used in many fields such as used as support prototypes. They are customized with different sizes and shapes. If you have an interest in TZM alloy rings, please feel free to contact us.

If you have any inquiry of TZM rings, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten WeChat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.