Seamless steel pipes are known as the “blood vessels” of industry and are important raw materials for national industrial construction and national defense construction, while piercing plugs made of molybdenum alloy are the most efficient tools for them.

Whether manufacturing airplanes, ships, trains, automobiles, boilers, power stations, or transporting oil, steam, water, or developing mineral deposits for geological drilling, seamless steel pipes are required and inseparable. It can be said that the development of many industries such as petroleum, chemical, steel, machinery, military, aerospace and other industries can not be moved forward without seamless steel pipes.

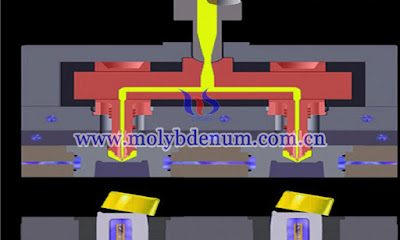

There are many kinds of seamless steel pipes and their production methods are also various. At present, the production lines for hot-rolled seamless pipes mainly include automatic pipe rolling mills, continuous pipe rolling mills, periodic pipe rolling mills, three-roll pipe rolling mills, pipe jacking mills and extruded steel pipe mills.

However, regardless of the production method, the decisive factor for product performance is molybdenum piercing plug. This material of plug is the most efficient perforated plug, which guarantees the good performance of seamless steel pipes.

Molybdenum piercing plug is also named molybdenum piercing mandrel, which is made of zirconium titanium molybdenum (TZM) alloy material. To pierce stainless steel pipes, the plugs must withstand high temperature and high stress. Molybdenum is one of the rare metals with characteristics of high melting point, excellent mechanical features, corrosion resistance and easy workability. The recrystallization at high temperatures produces a reduction of its mechanical properties such as UTS, hardness and toughness.

This reduction of the properties of pure molybdenum can be reduced by small additions of elements such as zirconium, titanium, boron and rare earth which increase the recrystallization temperatures and therefore the mechanical properties of such molybdenum alloys.

TZM is a kind of molybdenum alloy, which contains small amounts of titanium, zirconium and carbon. The piercing plug made of TZM material can extend its service life and improve the utilization rate.