Molybdenum target is mainly used in plasma sputtering industry. With the electric field, electron collided with the argon atom molybdenum target when fly to the substrate, then argon atoms and electrics were ionized .The electrics fly to the substrate while argon atoms accelerate to bomb the target, the neutral atoms (or molecules) in the target deposit on the substrate and become the coating.

Since the molybdenum resistant to high temperature and corrosion, molybdenum targets are widely used in petroleum chemical industry, aviation, machine manufacturing, and electronics semiconductor industries and so on.

We can provide molybdenum target that made with molybdenum powder which purity is 99.95%. High quality products have been made after decades of procedures such as pressing, sintering, rolling, cutting and surface grinding. Super sputtering target (single heavy reach to 120kg) is available at present.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月28日星期四

Rhenium and Tungsten (Molybdenum) Rhenium Alloy

Rhenium has several unique properties as follows:

High melting temperature

Extreme resistance to chemical erosion

Ability to maintain ductility after recrystallization

High electrical resistivity over a wide temperature range

Low vapor pressure

Resistant to oxidation at very high temperature

Good thermal shock resistance

W-Re alloy (tungsten rhenium alloy) is made of tungsten alloyed with 3%, 5%, 25% or 26% rhenium, which become more ductile and machineable. With good electrical properties, W-Re alloys are widely used as high temperature thermocouple materials.

Mo-Re alloy (molybdenum rhenium alloy) is molybdenum alloyed with 41% or 47.5% of rhenium (nominal content of Rhenium is 50%), which has good ductility, weld ability, formability, and strength. Mo-Re alloy keeps high ductile even after used in high temperature. Mo-Re alloys are widely used for electronics, nuclear, and space applications.

High melting temperature

Extreme resistance to chemical erosion

Ability to maintain ductility after recrystallization

High electrical resistivity over a wide temperature range

Low vapor pressure

Resistant to oxidation at very high temperature

Good thermal shock resistance

W-Re alloy (tungsten rhenium alloy) is made of tungsten alloyed with 3%, 5%, 25% or 26% rhenium, which become more ductile and machineable. With good electrical properties, W-Re alloys are widely used as high temperature thermocouple materials.

Mo-Re alloy (molybdenum rhenium alloy) is molybdenum alloyed with 41% or 47.5% of rhenium (nominal content of Rhenium is 50%), which has good ductility, weld ability, formability, and strength. Mo-Re alloy keeps high ductile even after used in high temperature. Mo-Re alloys are widely used for electronics, nuclear, and space applications.

If you have any inquiry of molybdenum products, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月26日星期二

Molybdenum Oxide Price Falls Slightly on Poor Steel Bidding

Chinese molybdenum price remains weak adjustment because steel bidding plans for ferro molybdenum are unclear and the market faces pressure. The latest price of molybdenum concentrate and molybdenum oxide falls slightly.

Inventory shortage in mines stabilizes molybdenum concentrate price; prices and quantity of steel biddings show poor performance and thus ferro molybdenum price is under pressure and manufacturers have strong risk aversion. Due to few new increased orders and weakening support from costs, prices in molybdenum chemical and product market is in a downward trend.

Jiangsu Dragons bid out 150 tonnes of ferro molybdenum in July with price of RMB 105.500 per tonne, down RMB 3,000 per tonne from last month; HBIS Group tenders 60 tonnes of ferro molybdenum for June in RMB 106,500 per tonne, down RMB 1,500 per tonne from compared with last time.

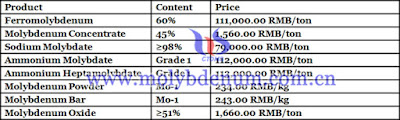

Prices of molybdenum products on Jun. 27, 2018

Picture of molybdenum oxide

Inventory shortage in mines stabilizes molybdenum concentrate price; prices and quantity of steel biddings show poor performance and thus ferro molybdenum price is under pressure and manufacturers have strong risk aversion. Due to few new increased orders and weakening support from costs, prices in molybdenum chemical and product market is in a downward trend.

Jiangsu Dragons bid out 150 tonnes of ferro molybdenum in July with price of RMB 105.500 per tonne, down RMB 3,000 per tonne from last month; HBIS Group tenders 60 tonnes of ferro molybdenum for June in RMB 106,500 per tonne, down RMB 1,500 per tonne from compared with last time.

Prices of molybdenum products on Jun. 27, 2018

Picture of molybdenum oxide

If you have any inquiry of molybdenum products, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月25日星期一

Tungsten and Molybdenum Furnace Components

Tungsten has the highest melting point of all metals as well as a remarkably high modulus of elasticity. Molybdenum also belongs to the refractory metals group with excellent thermal properties and is still easy to machine. So, tungsten, molybdenum and their alloy are the best choices for the all kinds of high temperature furnace. They can easily withstand even the most intense heat.

Tungsten and molybdenum furnace components

Chemical composition: Tungsten >99.95% ( percentage by weight)

Molybdenum >99.95%, molybdenum lanthanum alloy, TZM alloy

Specification: Round, square, special design according to drawing

Surface finish: < Ra3.2 shining furnace

Working temperature: 1500 ~ 2600 In Vacuum or deoxidize atmosphere

Produce Method: Powder Metallurgy

Main applications

Sapphire single crystal growth furnace, metallurgical industry furnace, vacuum furnace, high temperature furnace, silicon industry furnace, quartz glass, metal extracting, , machinery processing, glass and ceramic industries, etc.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Tungsten and molybdenum furnace components

Chemical composition: Tungsten >99.95% ( percentage by weight)

Molybdenum >99.95%, molybdenum lanthanum alloy, TZM alloy

Specification: Round, square, special design according to drawing

Surface finish: < Ra3.2 shining furnace

Working temperature: 1500 ~ 2600 In Vacuum or deoxidize atmosphere

Produce Method: Powder Metallurgy

Main applications

Sapphire single crystal growth furnace, metallurgical industry furnace, vacuum furnace, high temperature furnace, silicon industry furnace, quartz glass, metal extracting, , machinery processing, glass and ceramic industries, etc.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Brief Introduction To Tungsten Heavy Alloy

Tungsten heavy alloy is the generic name for tungsten-based, high-density alloy and contains nickel, copper and iron as additives for homogeneous sintering. The alloy material is classified according to composition, or tungsten content (90%-96%) and the sorts of additives.

Advantages

High density of 17-18.4Mg/m3

Excellent mechanical properties such as high vibrationdamping capacity and high Young's modulus

Excellent radiation-shielding property

High thermal conductivity with low thermal expansion coefficient

Higher high-temperature strength and thermal shock resistance

High oxidation resistance and corrosion resistance

Applications

X-ray devices both for medical and industrial use, radiation-shielding components for gamma-ray devices, andisotope containers

Vibrator balances for cellular phones, and flywheels

Boring bars and quills

Die parts for diecast dies, core pins and sleeves

Electrodes

Heat treatment furnace jigs

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Advantages

High density of 17-18.4Mg/m3

Excellent mechanical properties such as high vibrationdamping capacity and high Young's modulus

Excellent radiation-shielding property

High thermal conductivity with low thermal expansion coefficient

Higher high-temperature strength and thermal shock resistance

High oxidation resistance and corrosion resistance

Applications

X-ray devices both for medical and industrial use, radiation-shielding components for gamma-ray devices, andisotope containers

Vibrator balances for cellular phones, and flywheels

Boring bars and quills

Die parts for diecast dies, core pins and sleeves

Electrodes

Heat treatment furnace jigs

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月21日星期四

Molybdenum Pins

Properties: Recrystallization temperature between 1500oC and 1700oC.

ensile strength: 900N/mm2min..

Elongation: 15%-20%..

Tolerance: ±2%, .

Molybdenum pins are used for manufacturing halogen automotive lamps, as sealed lead-wire through hard-glass. The molybdenum pins are doped molybdenum wires. The arc-height of a wire sample of 200mm length, located on a glass plate, can be not greater relative to the imaginary string than 20mm. The pins have a very smooth and bright surface and the surface free of stain, dirt, oxides, drawing tracks, scratches and damages.

Molybdenum Pins have an even vivid surface ideal for use in manufacturing halogen lamps for automobiles .Materials are produced using crystallization, solid state and other ultra high purification processes such as sublimation. American Elements specializes in producing custom compositions for commercial and research applications and for new proprietarytechnologies.

American Elements casts any of the rare earth metals and most other advanced materials into rod, bar or plate form, as well as other machined shapes and through other processes such as nanoparticles (See also application discussion at Nanotechnology Information and at Quantum Dots) and in the form of solutions and organometallics.

If you have any inquiry of molybdenum pins, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

ensile strength: 900N/mm2min..

Elongation: 15%-20%..

Tolerance: ±2%, .

Molybdenum pins are used for manufacturing halogen automotive lamps, as sealed lead-wire through hard-glass. The molybdenum pins are doped molybdenum wires. The arc-height of a wire sample of 200mm length, located on a glass plate, can be not greater relative to the imaginary string than 20mm. The pins have a very smooth and bright surface and the surface free of stain, dirt, oxides, drawing tracks, scratches and damages.

Molybdenum Pins have an even vivid surface ideal for use in manufacturing halogen lamps for automobiles .Materials are produced using crystallization, solid state and other ultra high purification processes such as sublimation. American Elements specializes in producing custom compositions for commercial and research applications and for new proprietarytechnologies.

American Elements casts any of the rare earth metals and most other advanced materials into rod, bar or plate form, as well as other machined shapes and through other processes such as nanoparticles (See also application discussion at Nanotechnology Information and at Quantum Dots) and in the form of solutions and organometallics.

If you have any inquiry of molybdenum pins, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Chinese Molybdenum Price Is in a Downward Trend

Analysis of latest molybdenum market from Chinatungsten Online:

Chinese molybdenum price is in a downward trend at present amid the latest price of molybdenum concentrate and sodium molybdate falls slightly and molybdenum powder price is unchanged from the previous trading day. Weak market demand, poor performance of steel biddings and weakening support from raw material side are the main reasons.

Insiders now are negative on the market outlook and manufacturers cutting their product profits for more orders lower transaction prices. Affected by the environmental checks, the operating rate in mines and smelting factories is low. In the short term, deadlocked supply and demand will continue and steel biddings at the end of this month would be the focus of the market.

Prices of molybdenum products on Jun. 22, 2018

Picture of molybdenum disulfide

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Chinese molybdenum price is in a downward trend at present amid the latest price of molybdenum concentrate and sodium molybdate falls slightly and molybdenum powder price is unchanged from the previous trading day. Weak market demand, poor performance of steel biddings and weakening support from raw material side are the main reasons.

Insiders now are negative on the market outlook and manufacturers cutting their product profits for more orders lower transaction prices. Affected by the environmental checks, the operating rate in mines and smelting factories is low. In the short term, deadlocked supply and demand will continue and steel biddings at the end of this month would be the focus of the market.

Prices of molybdenum products on Jun. 22, 2018

Picture of molybdenum disulfide

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Molybdenum Metal & Alloys

Molybdenum metal is usually produced by powder metallurgy techniques in which Mo powder is hydrostratically compacted and sintered at about 2100°C. Hot working is done in the 870-1260°C range. Moly forms a volatile oxide when heated in air above about 600°C and therefore high temperature applications are limited to non-oxidizing or vacuum environments.

Moly alloys have excellent strength and mechanical stability at high temperatures (up to 1900°C). Their high ductility and toughness provide a greater tolerance for imperfections and brittle fracture than ceramicssintered-molybdenum-parts.

The unique properties of molybdenum alloys are utilised in many applications:

High temperature heating elements, radiation shields, extrusions, forging dies, etc;

Rotating X-ray anodes used in clinical diagnostics;

Glass melting furnace electrodes and components that are resistant to molten glass;

Heat sinks with thermal expansivity matching silicon for semiconductor chip mounts;

Sputtered layers, only Ångstroms (10-7 mm) thick, for gates and interconnects on integrated circuit chips;

Sprayed coatings on automotive piston rings and machine components to reduce friction and improve wear.

For specialised applications, Mo is alloyed with many other metals:

Mo-tungsten alloys are noted for exceptional resistance to molten zinc;

Mo is clad with copper to provide low expansion and high conductivity electronic circuit boards;

Mo-25% rhenium alloys are used for rocket engine components and liquid metal heat exchangers which must be ductile at room temperature.

If you have any inquiry of molybdenum sheets, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Moly alloys have excellent strength and mechanical stability at high temperatures (up to 1900°C). Their high ductility and toughness provide a greater tolerance for imperfections and brittle fracture than ceramicssintered-molybdenum-parts.

The unique properties of molybdenum alloys are utilised in many applications:

High temperature heating elements, radiation shields, extrusions, forging dies, etc;

Rotating X-ray anodes used in clinical diagnostics;

Glass melting furnace electrodes and components that are resistant to molten glass;

Heat sinks with thermal expansivity matching silicon for semiconductor chip mounts;

Sputtered layers, only Ångstroms (10-7 mm) thick, for gates and interconnects on integrated circuit chips;

Sprayed coatings on automotive piston rings and machine components to reduce friction and improve wear.

For specialised applications, Mo is alloyed with many other metals:

Mo-tungsten alloys are noted for exceptional resistance to molten zinc;

Mo is clad with copper to provide low expansion and high conductivity electronic circuit boards;

Mo-25% rhenium alloys are used for rocket engine components and liquid metal heat exchangers which must be ductile at room temperature.

If you have any inquiry of molybdenum sheets, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月18日星期一

Molybdenum Disc

Molybdenum Disc Characteristics:

They have smooth and clean surface, their flat roughness is down to Ra 1.6.

They have good conductions, small linear expansion coefficient and good heat-resistance.

Specifications:

Diameter Range: 7 ~ 100mm Thickness Range: 0.8 ~ 4.0mm.

Square Piece: 4 ~ 25mm2 Thickness: 0.5 ~ 1.5mm

.

Parameters:

Density: 10.15g/cm3 Resistivity: Less than 6.26 × 10-6Ωcm.

Linear Expansion Coefficient: 4.0 × 10-6K-1 ~ 6.4 × 10-6K-1.

Applications:

Be made to the thyristor silicon parts and its electric parts supporting base material.

If you have any inquiry of molybdenum disc, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

They have smooth and clean surface, their flat roughness is down to Ra 1.6.

They have good conductions, small linear expansion coefficient and good heat-resistance.

Specifications:

Diameter Range: 7 ~ 100mm Thickness Range: 0.8 ~ 4.0mm.

Square Piece: 4 ~ 25mm2 Thickness: 0.5 ~ 1.5mm

.

Parameters:

Density: 10.15g/cm3 Resistivity: Less than 6.26 × 10-6Ωcm.

Linear Expansion Coefficient: 4.0 × 10-6K-1 ~ 6.4 × 10-6K-1.

Applications:

Be made to the thyristor silicon parts and its electric parts supporting base material.

If you have any inquiry of molybdenum disc, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月14日星期四

Brief Introduction To Molybdenum Electrode

Molybdenum (Mo) is commonly used as back contacts for Cu(In,Ga)Se2(CIGS) thin film solar cells because it has the good molybdenum electrode electrical properties of an ohmic contactand is an inert, mechanically durable substrate duringthe absorber film growth. In general, Mo is deposited bydc sputtering onto soda-lime glass substrates. The elec-trical and the mechanical properties of sputtered refrac-tory metal films are known to vary with the working gaspressure .

CIGS thin film growth occurs at tempera-tures > 500 and at these temperatures, the thermallyinduced extrinsic stresses in the glass-Mo structure maycause bending or mechanical distortion of substrate. During the formation of CIGS films, Na ions diffuse fromthe soda-lime glass substrate through the Mo back con-tact into the absorber layer. The diffusion of Na into theabsorber film depends on the deposition conditions of theMo back contact .

Molybdenum films were deposited on soda-lime glass substrates by using DC magnetron sputtering. Their structural and morphological properties and their electrical resistivities were analyzed with respect to the working gas (Ar) pressure. The electrical resistivity of the Mo films monotonically increased as the gas pressure was increased. The films showed a (110) preferred orientation, regardless of the working gas pressure.

The surface morphology of the films changed from an elon-gated grain structure at lower working pressures to a porous nodular shape at higher pressures. The surface roughness of the films increased with the working gas pressure. Secondary ion mass spectrometry data showed that Na diffusion from the soda lime glass substrate through the Moback contact was high, for the film sputtered at 5 mTorr. Cu(InGa)Se2 solar cells fabricated on Mofilms sputtered at 5 mTorr showed the best conversion efficiencies.

If you have any inquiry of molybdenum electrode, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

CIGS thin film growth occurs at tempera-tures > 500 and at these temperatures, the thermallyinduced extrinsic stresses in the glass-Mo structure maycause bending or mechanical distortion of substrate. During the formation of CIGS films, Na ions diffuse fromthe soda-lime glass substrate through the Mo back con-tact into the absorber layer. The diffusion of Na into theabsorber film depends on the deposition conditions of theMo back contact .

Molybdenum films were deposited on soda-lime glass substrates by using DC magnetron sputtering. Their structural and morphological properties and their electrical resistivities were analyzed with respect to the working gas (Ar) pressure. The electrical resistivity of the Mo films monotonically increased as the gas pressure was increased. The films showed a (110) preferred orientation, regardless of the working gas pressure.

The surface morphology of the films changed from an elon-gated grain structure at lower working pressures to a porous nodular shape at higher pressures. The surface roughness of the films increased with the working gas pressure. Secondary ion mass spectrometry data showed that Na diffusion from the soda lime glass substrate through the Moback contact was high, for the film sputtered at 5 mTorr. Cu(InGa)Se2 solar cells fabricated on Mofilms sputtered at 5 mTorr showed the best conversion efficiencies.

If you have any inquiry of molybdenum electrode, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

"Water and Soil Disease" Caused by Molybdenum Lack

The average contents of molybdenum is 1.3 PPM, in the earth crust. Fossil fuels containing molybdenum in natural water body is in very low concentrations, and molybdenum in sea water of the average concentration is 14 micrograms/l.

But due to the Human activities widely used molybdenum and burning of molybdenum content fuel , so increase the molybdenum in the environment circulation.

What is more Weathering make the molybdenum released from the rock. Molybdenum distribution are not regularly, thus cause some areas lack of molybdenum and appear "water and soil disease".

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

But due to the Human activities widely used molybdenum and burning of molybdenum content fuel , so increase the molybdenum in the environment circulation.

What is more Weathering make the molybdenum released from the rock. Molybdenum distribution are not regularly, thus cause some areas lack of molybdenum and appear "water and soil disease".

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

The Weakness in Chinese Molybdenum Price

Chinese molybdenum price is weak amid the price of molybdenum concentrate and molybdenum oxide declines slightly and ferro molybdenum price remains unchanged. Representative miners in Heilongjiang lowered product offers earlier this week, which enhances traders’ negative mentality. Trading atmosphere is quiet at present.

In the molybdenum concentrate market, some sellers with weak market confidence decline product prices for more shipments, but considering the support from supply side, the adjustment is limited. Although the production cost in the ferro molybdenum market shows signs of decline, steel bidding prices are in a relatively low level. Ferro molybdenum manufacturers are caught in heavy wait-and-see atmosphere.

Prices of molybdenum products on Jun. 13, 2018

Picture of ferro molybdenum

In the molybdenum concentrate market, some sellers with weak market confidence decline product prices for more shipments, but considering the support from supply side, the adjustment is limited. Although the production cost in the ferro molybdenum market shows signs of decline, steel bidding prices are in a relatively low level. Ferro molybdenum manufacturers are caught in heavy wait-and-see atmosphere.

Prices of molybdenum products on Jun. 13, 2018

Picture of ferro molybdenum

If you have any inquiry of molybdenum products, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月11日星期一

Molybdenum Products

Many products flow from the mining and processing of ores containing molybdenite (MoS2), including:

Chemical Mo products

Used in catalysts, polymer compounding, corrosion inhibitors, and high-performance lubricant formulations, these include pure molybdic oxide and molybdates, and lubricant grade MoS2.

Meltstock products

Used as alloy additions to iron, steel, nickel, and titanium alloys, these include technical Mo oxide, ferromolybdenum, and Mo metal pellets.

Mo metal products

These include powder, Mo metal and Mo-base alloy mill products, and products fabricated from them.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Chemical Mo products

Used in catalysts, polymer compounding, corrosion inhibitors, and high-performance lubricant formulations, these include pure molybdic oxide and molybdates, and lubricant grade MoS2.

Meltstock products

Used as alloy additions to iron, steel, nickel, and titanium alloys, these include technical Mo oxide, ferromolybdenum, and Mo metal pellets.

Mo metal products

These include powder, Mo metal and Mo-base alloy mill products, and products fabricated from them.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Molybdenum Rod

Molybdenum Rod

Standard: ASTM B387

Material: Mo >99.95%

Density: >10.2g/cc

Surface Finish:

Black - Surface is "as swaged" or "as drawn"; retaining a coating of processing lubricants and oxides.

Cleaned - Surface is chemically cleaned to remove all lubricants and oxides.

Ground - Surface is center-less ground to remove all coating and to achieve precise diameter control.

Specification:

Molybdenum rod is manufactured as random length pieces or cut to customers' desired lengths in diameters ranging from 0.080 inches to 6.00 inches.

Applications:

Molybdenum rod can be stretched into molybdenum wire, molybdenum electrode and it also can be applied to steel-making additives, Electric vacuum parts, gas pipes, lead-wire, pole, side bar, daily-use glass, optical glass, insulation material and glass fiber.

If you have any inquiry of molybdenum rod, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Standard: ASTM B387

Material: Mo >99.95%

Density: >10.2g/cc

Surface Finish:

Black - Surface is "as swaged" or "as drawn"; retaining a coating of processing lubricants and oxides.

Cleaned - Surface is chemically cleaned to remove all lubricants and oxides.

Ground - Surface is center-less ground to remove all coating and to achieve precise diameter control.

Specification:

Molybdenum rod is manufactured as random length pieces or cut to customers' desired lengths in diameters ranging from 0.080 inches to 6.00 inches.

Applications:

Molybdenum rod can be stretched into molybdenum wire, molybdenum electrode and it also can be applied to steel-making additives, Electric vacuum parts, gas pipes, lead-wire, pole, side bar, daily-use glass, optical glass, insulation material and glass fiber.

If you have any inquiry of molybdenum rod, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月8日星期五

Molybdenum Wire Applications

The molybdenum wire is principally used in the high-temperature field of molybdenum furnace and radio tube outlets, also in thinning the molybdenum filament, and the molybdenum rod in heating materials for high-temperature furnace, and side-bracket/bracket/outlets wire for heating materials.

Molybdenum wire recommend applications:

Molybdenum wire recommend applications:

If you have any inquiry of molybdenum wire, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月6日星期三

Chinese Molybdenum Market Stabilizes on Weak Demand

The latest price of ammonium molybdate and ammonium heptamolvbdate falls slightly while molybdenum powder price remained unchanged in Chinese molybdenum market. Disparity in supply and demand at each end of the industry chain affects the dissension of businesses and central enterprises operate mainly replying on costs.

Molybdenum concentrate traders are more active in inquiry, which increases market trading. While miners with good mentality keep firm offers. In the ferro molybdenum market, prices of steel biddings change sharply, but still are weak. Risks of cost overhang of manufacturers weaken trading willingness. Weak demand makes businesses selling their products at low prices, so product prices in the molybdenum chemical and product market decline slightly.

Prices of molybdenum products on Jun. 07, 2018

Picture of FeMo powder

Molybdenum concentrate traders are more active in inquiry, which increases market trading. While miners with good mentality keep firm offers. In the ferro molybdenum market, prices of steel biddings change sharply, but still are weak. Risks of cost overhang of manufacturers weaken trading willingness. Weak demand makes businesses selling their products at low prices, so product prices in the molybdenum chemical and product market decline slightly.

Prices of molybdenum products on Jun. 07, 2018

Picture of FeMo powder

If you have any inquiry of molybdenum products, please feel free to contact us:

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月5日星期二

What Is Copper Indium Gallium Diselenide (CIGS) ?

Copper indium gallium diselenide (CIGS) technology is regarded by some as the most promising thin-film PV contender to the c-Si due to its high conversion efficiencies, potential cost effectiveness and incrementally improving manufacturability.

In order to stay successful and remain profitable, CIGS manufacturers must further increase the ratio of conversion efficiency to manufacturing cost of their modules. The former relies primarily on new technological advances, such as the advanced engineering solutions for the absorber layer, interface adjustment and use of better and purer materials. The latter is intimately related to the improved production throughput and yield, better material utilization and improved logistics.

In a typical CIGS device, fabrication starts with the deposition of a sputtered molybdenum (Mo) electrode on a substrate, such as soda-lime glass. The use of Mo as the back electrode has remained unchanged since the inception of the CIGS technology. In fact, molybdenum is one of the few metals that remain relatively inert during the CIGS high-temperature (>500 °C) selenization process.

Despite the fact that CIGS manufacturing recipes vary significantly between individual module producers, the number of “knobs” available in tuning sputter-deposited Mo electrodes is always quite limited. Recipe differences include sputtering pressure and power, the levels of intentionally added impurities, compositional grading profile, and the number and position of sputtering targets in the coater, etc. All of these variables are crucial in achieving high conductivity, proper electrical matching to the CIGS, good adhesion and long-term stability.

The Mo electrode should be about 400-800 nm thick to achieve 0.2 – 0.5 Ohm/sq sheet resistance. Depending on the CIGS fabrication method, the back electrode represents 7-20% of the manufacturing cost of the complete module. There are a number of strong economical and technological reasons for CIGS companies to outsource the back Mo electrode from a large-scale glass manufacturer.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

In order to stay successful and remain profitable, CIGS manufacturers must further increase the ratio of conversion efficiency to manufacturing cost of their modules. The former relies primarily on new technological advances, such as the advanced engineering solutions for the absorber layer, interface adjustment and use of better and purer materials. The latter is intimately related to the improved production throughput and yield, better material utilization and improved logistics.

In a typical CIGS device, fabrication starts with the deposition of a sputtered molybdenum (Mo) electrode on a substrate, such as soda-lime glass. The use of Mo as the back electrode has remained unchanged since the inception of the CIGS technology. In fact, molybdenum is one of the few metals that remain relatively inert during the CIGS high-temperature (>500 °C) selenization process.

Despite the fact that CIGS manufacturing recipes vary significantly between individual module producers, the number of “knobs” available in tuning sputter-deposited Mo electrodes is always quite limited. Recipe differences include sputtering pressure and power, the levels of intentionally added impurities, compositional grading profile, and the number and position of sputtering targets in the coater, etc. All of these variables are crucial in achieving high conductivity, proper electrical matching to the CIGS, good adhesion and long-term stability.

The Mo electrode should be about 400-800 nm thick to achieve 0.2 – 0.5 Ohm/sq sheet resistance. Depending on the CIGS fabrication method, the back electrode represents 7-20% of the manufacturing cost of the complete module. There are a number of strong economical and technological reasons for CIGS companies to outsource the back Mo electrode from a large-scale glass manufacturer.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

2018年6月3日星期日

Applications of MoW (Molybdenum-Tungsten)

MoW (Molybdenum-Tungsten)

The alloying of molybdenum with tungsten leads to better corrosion resistance against molten zinc. We produce standardized MoW alloys with 30 weight% of tungsten (MOLY B60) and 50 weight% W.mocu

MoW Advantages compared to pure Mo:

higher recrystallization temperature (approx. 100 'C)

better corrosion resistance against molten zinc .

higher strength.

MoW Advantages compared to pure W:

better formability

lower density

MoW Typical areas of applications:

components for zinc processing, e.g. pump components, nozzles, thermocouple sheaths .

stirrers for the glass industry .

Sputter targets for coating technology.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

The alloying of molybdenum with tungsten leads to better corrosion resistance against molten zinc. We produce standardized MoW alloys with 30 weight% of tungsten (MOLY B60) and 50 weight% W.mocu

MoW Advantages compared to pure Mo:

higher recrystallization temperature (approx. 100 'C)

better corrosion resistance against molten zinc .

higher strength.

better formability

lower density

MoW Typical areas of applications:

components for zinc processing, e.g. pump components, nozzles, thermocouple sheaths .

stirrers for the glass industry .

Sputter targets for coating technology.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

Molybdenum Alloy

Molybdenum Alloy (Titanium-Zirconium-Molybdenum)

TZM is a solid-solution hardened and particle-strengthened molybdenum based alloy. The development of a Mo-Ti solid solution and the fine dispersed Ti-carbides are responsible for the excellent strength properties at temperatures up to 1400'C. The average nominal chemical composition in weight%: 0.5 Ti, 0.08 Zr, 0.02 C, remainder Mo.

Molybdenum Alloy Advantages compared to pure Mo:

TZM material has better creep resistance and higher recrystallization temperature .

TZM has better high-temperature strength and better welding properties.

Molybdenum Alloy Typical areas of application:

TZM can be used to make components for HIP, sintering and heat treatment furnaces, and boats for annealing and sintering processes (temperatures up to 1400 'C)

TZM can be used for rotating anodes for medical diagnostics and forming tools such as hot runner nozzles for plastic injection moulding .

TZM can be used to make moulds for light-alloy casting and billets for the isothermal forging.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

TZM is a solid-solution hardened and particle-strengthened molybdenum based alloy. The development of a Mo-Ti solid solution and the fine dispersed Ti-carbides are responsible for the excellent strength properties at temperatures up to 1400'C. The average nominal chemical composition in weight%: 0.5 Ti, 0.08 Zr, 0.02 C, remainder Mo.

Molybdenum Alloy Advantages compared to pure Mo:

TZM material has better creep resistance and higher recrystallization temperature .

TZM has better high-temperature strength and better welding properties.

Molybdenum Alloy Typical areas of application:

TZM can be used to make components for HIP, sintering and heat treatment furnaces, and boats for annealing and sintering processes (temperatures up to 1400 'C)

TZM can be used for rotating anodes for medical diagnostics and forming tools such as hot runner nozzles for plastic injection moulding .

TZM can be used to make moulds for light-alloy casting and billets for the isothermal forging.

If you have any inquiry of molybdenum products, please feel free to contact us:

Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595

Fax: +86 592 5129797

Scan QR code of Chinatungsten Wechat platform to follow up the daily latest price and market of tungsten, molybdenum and rare earth.

订阅:

评论 (Atom)