Nowadays, hot runner system and cold runner system are two of the most popular methods for plastic injection molding in the world. Here comes the question. If you would like to produce mobile phone cases and keyboards, which system you should use?

The main difference for two systems is that the later one can inject plastic directly into the part cavity. This direct injection keeps the runner at a high temperature. The only component that needs to be removed in each cycle is the part itself. Therefore, the mold can be circulated again very quickly. Since the injection point is much smaller, the final plastic product looks better, thus achieving high details and smooth surfaces. Increased cycle time and reduced plastic waste make it ideal for mass production.

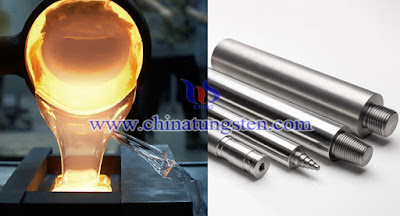

The choice of nozzle material is related to the production efficiency, cost and quality of the finished product. Titanium-zirconium-molybdenum (TZM) alloy is a particle-reinforced molybdenum-based alloy containing titanium, zirconium and carbon. It is widely used in aerospace, aviation and other industries, and can be used as nozzle material, valve body, gas pipeline material, gate tube material, die-casting mold, heating elements and heat shields for high-temperature furnaces, etc.

Compared with pure molybdenum, TZM alloy material has better creep resistance and welding performance, and a higher crystallization temperature. Due to its excellent high temperature performance and corrosion resistance, TZM rods are often processed into nozzle tips for hot runner systems.

At the same time, the system is also accompanied by some shortcomings, such as the system itself is larger and more complex, resulting in longer setup time and increased installation costs. Different systems are suitable for different products. Hot runners are suitable for mobile phone cases, bottle caps and items that require a lot of cheap parts; cold runners are suitable for keyboards, electronic casings and covers that can hide defects, and small batch production. Understand the inherent advantages and disadvantages of the two systems in order to choose the most suitable for their actual production needs.

Chinatungsten Online are professional manufacturer of molybdenum for more than two decades. If you have got the purchasing plan for TZM rod, please feel free to contact us.